Dunbar Automatic Buttering Device

Instructions on Automatic Buttering Device by Dunbar

Dunbar Automatic Buttering Device

by Bruce Wm. Anderson

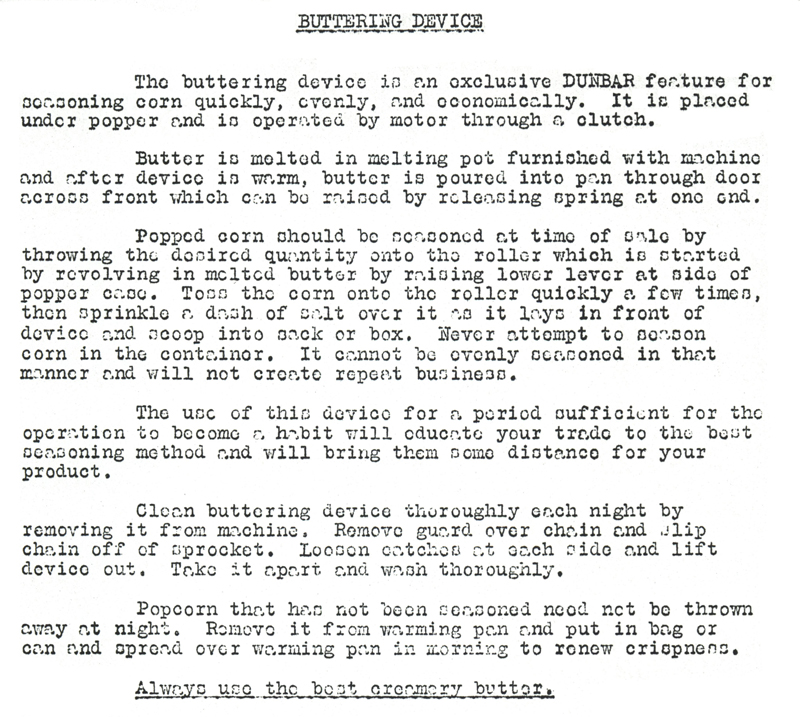

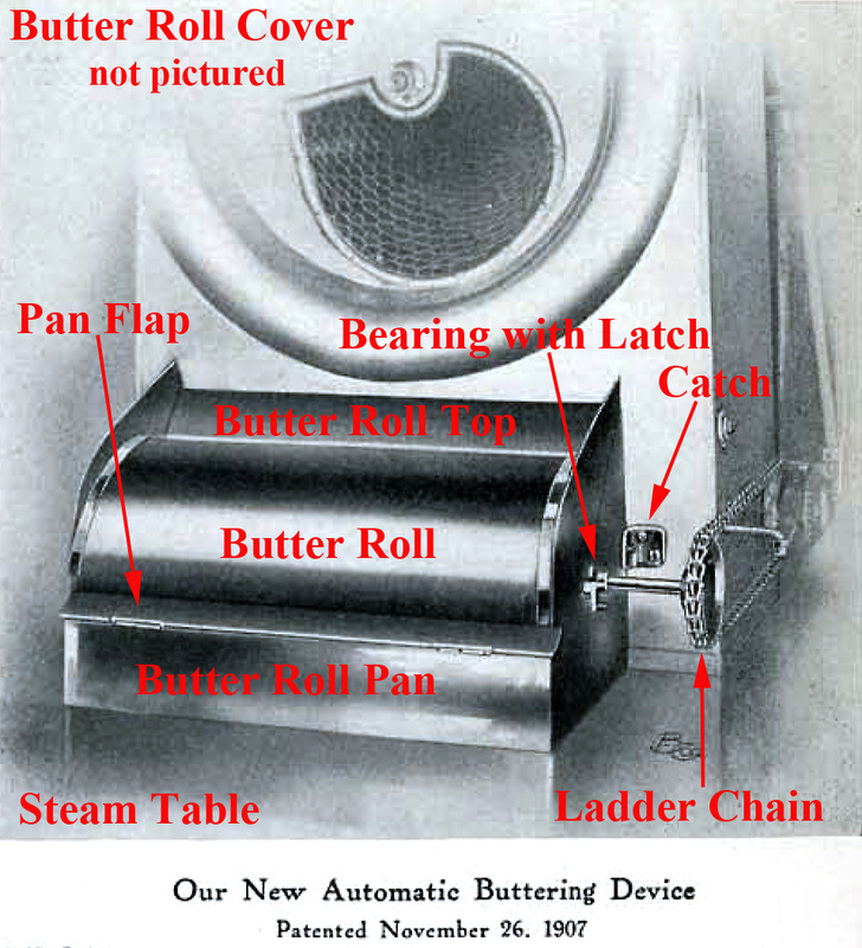

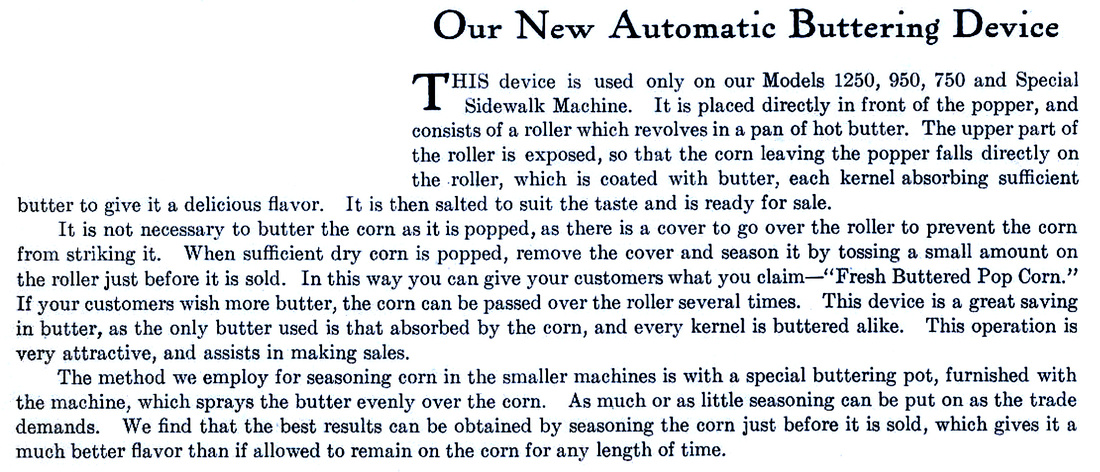

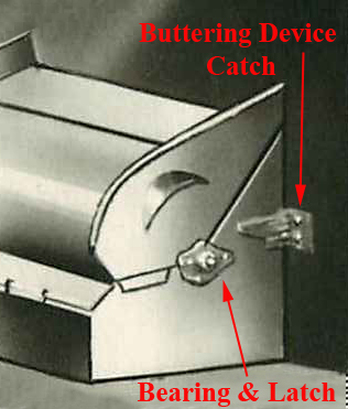

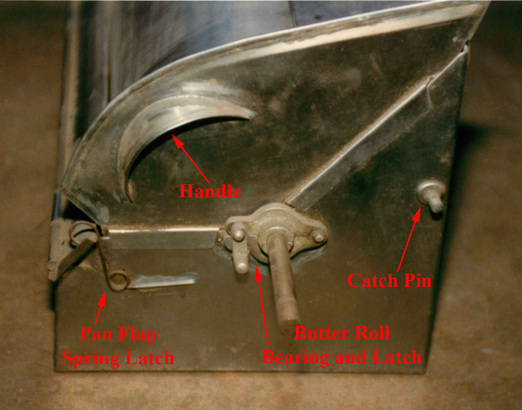

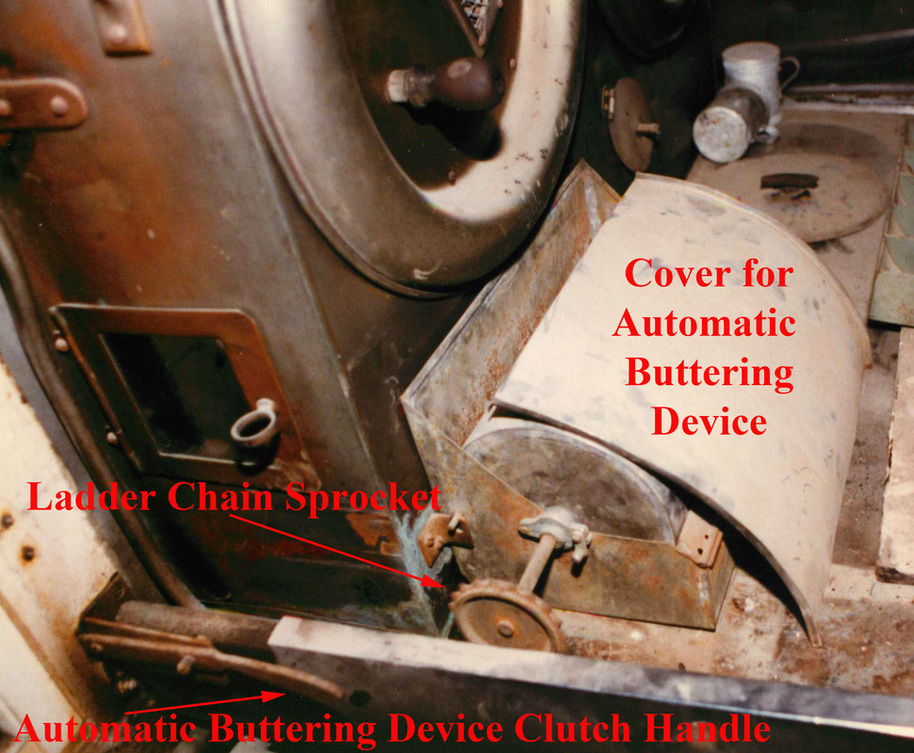

Dunbar & Co patented their Automatic Buttering Device on November 26, 1907 according to their literature (Picture 1 factory catalog). (In 1990, an unsuccessful search was made at the Library of Congress for this patent.) The Automatic Buttering Device consists of a roller that revolves in a pan of melted butter. The roller is driven by a ladder chain (Picture 2) which is controlled by a clutch and a gear reduction drive (Picture 3) which then connects it to the steam engine drivetrain. The buttering device pan has a flap on the front side allowing for adding the melted butter (Picture 1) and a top partial cover which is kept in place unless the buttering device is being cleaned (Picture 1). The butter roll is held into the bottom half of the butter device by two bearings with latches (Pictures 4, 5, 6, & 7). The flap is held closed by a spring latch (Picture 5). The automatic buttering device is held in position in front of the Dunbar Celebrated Rotary Dry Popper by two catches (Pictures 4, 5, 6, & 7).

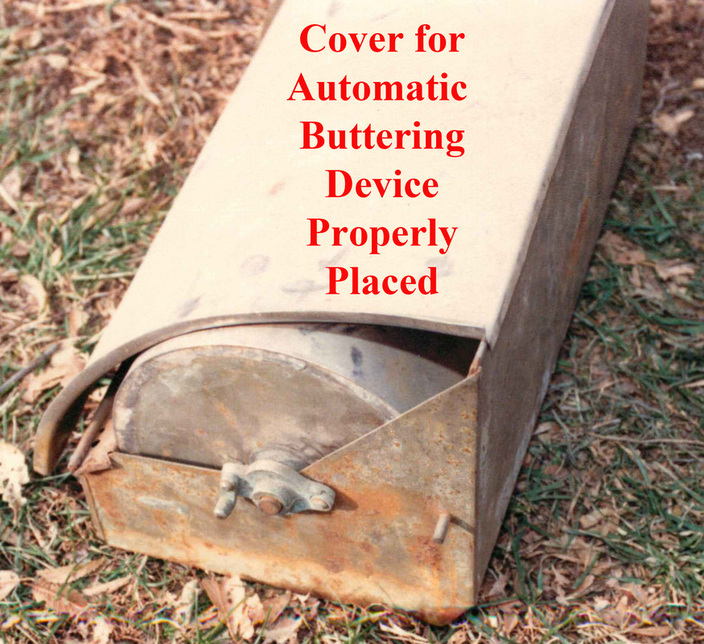

There is also a top cover (Pictures 8, 9, & 10) that covers the entire butter roll surface keeping popped popcorn from being seasoned when not needed. The popcorn can be automatically buttered by removing the cover over the Automatic Buttering Device and engaging the clutch (Pictures 8 & 9) which causes the roller to be covered with butter as it rotates through the melted butter in the bottom of the pan. The popped popcorn tumbles out of the popper and falls onto the rotating butter coated roller which then automatically seasons the popcorn. This is a great timesaver if you are selling all of the popcorn as you produce it. Popcorn can be popped in advance and not automatically buttered by placing the cover over the Automatic Buttering Device and disengaging its clutch. The popcorn is then moved to the side of the steam table where it is kept warm. As fresh buttered popcorn is needed the cover may be removed from the Automatic Buttering Device and the clutch engaged once again causing the roller to rotate. The dry popcorn can then be tossed against the rotating butter covered roller seasoning it the desired amount after which the seasoned popcorn can be boxed and sold.

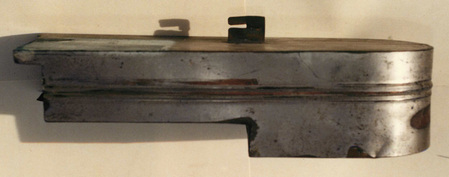

The Automatic Buttering Device should be kept clean by removing the cover over the ladder chain (Pictures 8, 11, 12, & 13), sliding the ladder chain off of its sprocket on the butter roll and removing the Automatic Buttering Device from the front of the Rotary Popper. The top of the Automatic Buttering Device should be removed, the bearing latches unlatched on each side of the butter roll, the butter roll removed from the pan, and all pieces should be thoroughly washed and dried preparing it for the next day’s use.

At the beginning of the day, butter can be melted over the stove (Picture 14) and poured into the buttering device through the front flap. During the day the butter will be kept melted by the heat of the steam table being transferred through the bottom of the Automatic Buttering Device.

There is also a top cover (Pictures 8, 9, & 10) that covers the entire butter roll surface keeping popped popcorn from being seasoned when not needed. The popcorn can be automatically buttered by removing the cover over the Automatic Buttering Device and engaging the clutch (Pictures 8 & 9) which causes the roller to be covered with butter as it rotates through the melted butter in the bottom of the pan. The popped popcorn tumbles out of the popper and falls onto the rotating butter coated roller which then automatically seasons the popcorn. This is a great timesaver if you are selling all of the popcorn as you produce it. Popcorn can be popped in advance and not automatically buttered by placing the cover over the Automatic Buttering Device and disengaging its clutch. The popcorn is then moved to the side of the steam table where it is kept warm. As fresh buttered popcorn is needed the cover may be removed from the Automatic Buttering Device and the clutch engaged once again causing the roller to rotate. The dry popcorn can then be tossed against the rotating butter covered roller seasoning it the desired amount after which the seasoned popcorn can be boxed and sold.

The Automatic Buttering Device should be kept clean by removing the cover over the ladder chain (Pictures 8, 11, 12, & 13), sliding the ladder chain off of its sprocket on the butter roll and removing the Automatic Buttering Device from the front of the Rotary Popper. The top of the Automatic Buttering Device should be removed, the bearing latches unlatched on each side of the butter roll, the butter roll removed from the pan, and all pieces should be thoroughly washed and dried preparing it for the next day’s use.

At the beginning of the day, butter can be melted over the stove (Picture 14) and poured into the buttering device through the front flap. During the day the butter will be kept melted by the heat of the steam table being transferred through the bottom of the Automatic Buttering Device.

Picture 1 and Writeup Below from Dunbar Catalogs

Picture 8

Picture 9

Picture 10

Picture 13

Butter Chain Guard - Side Towards Popper

Butter Chain Guard - Side Towards Popper

Picture 14

Stove for Melting Butter Located between the Steam Engine and the Boiler

Stove for Melting Butter Located between the Steam Engine and the Boiler