Dunbar Boiler

By

Bruce Wm. Anderson

Picture 1 Dunbar Copper Boiler

Picture 2 Dunbar Copper Boiler - Longitudinal Brazed Seam

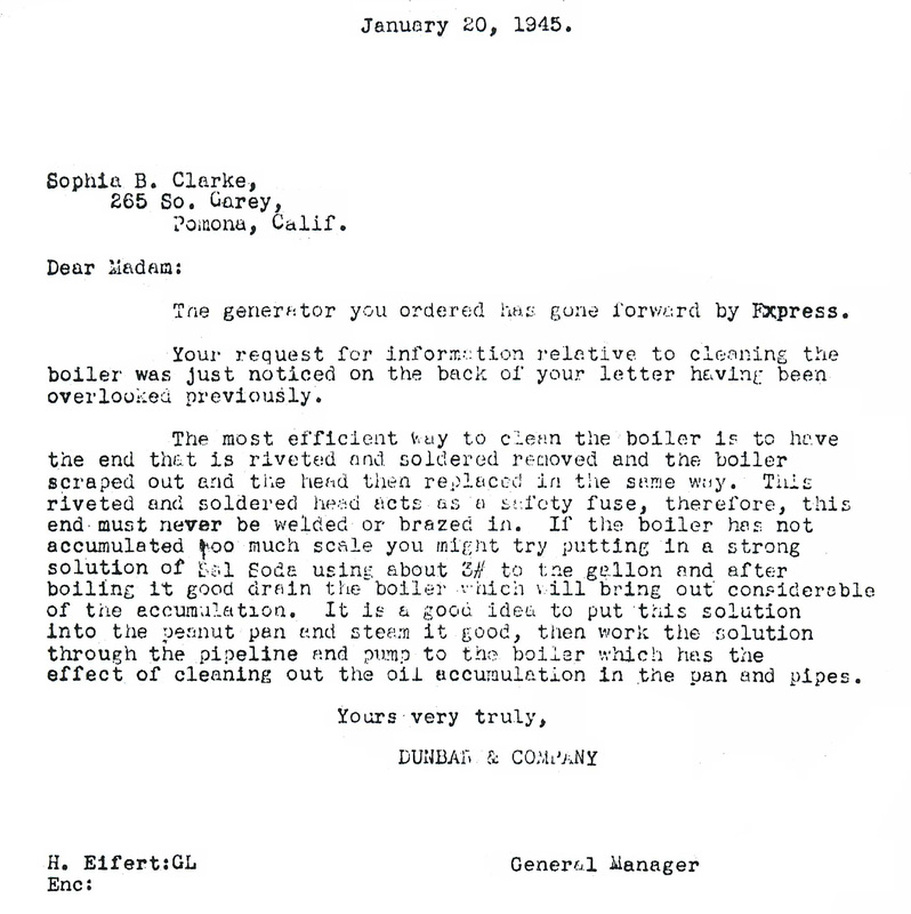

The Boiler (Pictures 1 - 6) is made of corrugated copper sides, spun copper ends, and a brass stay rod with cast iron nuts with flanges. One end is seamed and it and the longitudinal seam are brazed together. The second end is riveted and soldered. This head acts as a safety fuse and must never be brazed or welded in. It holds approximately 5 gallons of water. In the carbon copy letter below Dunbar and Co explained how to clean the their boiler to an owner of a 1200 Dunbar Popcorn Wagon.

Carbon Copy of Letter Sent by Dunbar & Co about Cleaning Boilers