Dunbar Pop Off or Safety Valve

by

Bruce Wm. Anderson

Description from Dunbar Catalogs

Shows an Early Pop Off Valve that is Pipe Vented with No Cap

Screwed on Cap was Added to Prevent Steam Burns

Shows an Early Pop Off Valve that is Pipe Vented with No Cap

Screwed on Cap was Added to Prevent Steam Burns

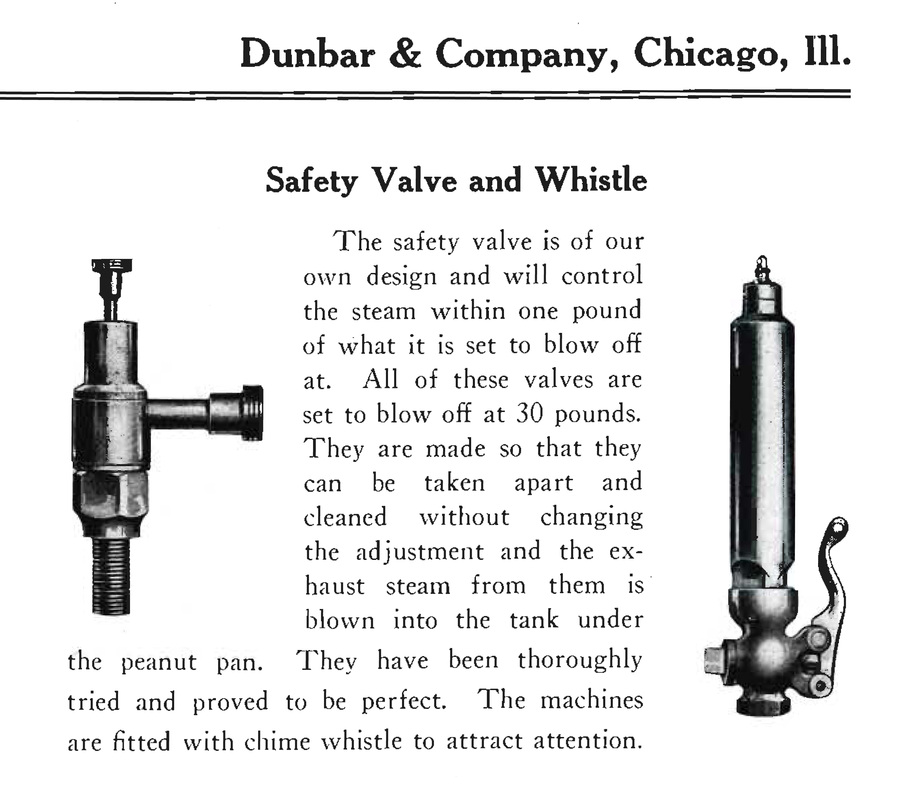

The safety steam Pop Off Valve (Pictures 1 and 2) does not allow the boiler steam pressure to go over 30 pounds. Normal working pressures are approximately 15 pounds on a free running nonbinding drivetrain. At 30 pounds steam is allowed to escape through the Pop Off Valve and directed back into the water tank through a 1/8 inch pipe threaded hole for recycling and reuse of the steam (water) on the larger machines. The steam is vented into the air on the smaller machines through an unthreaded 7/32” hole. The early Pop Off Valves did not have the threaded cover that protects the operator from escaping steam and hot water during a Pop Off (venting) from the top of the Pop Off Valve.