Please watch the above video "This Truck Matters."

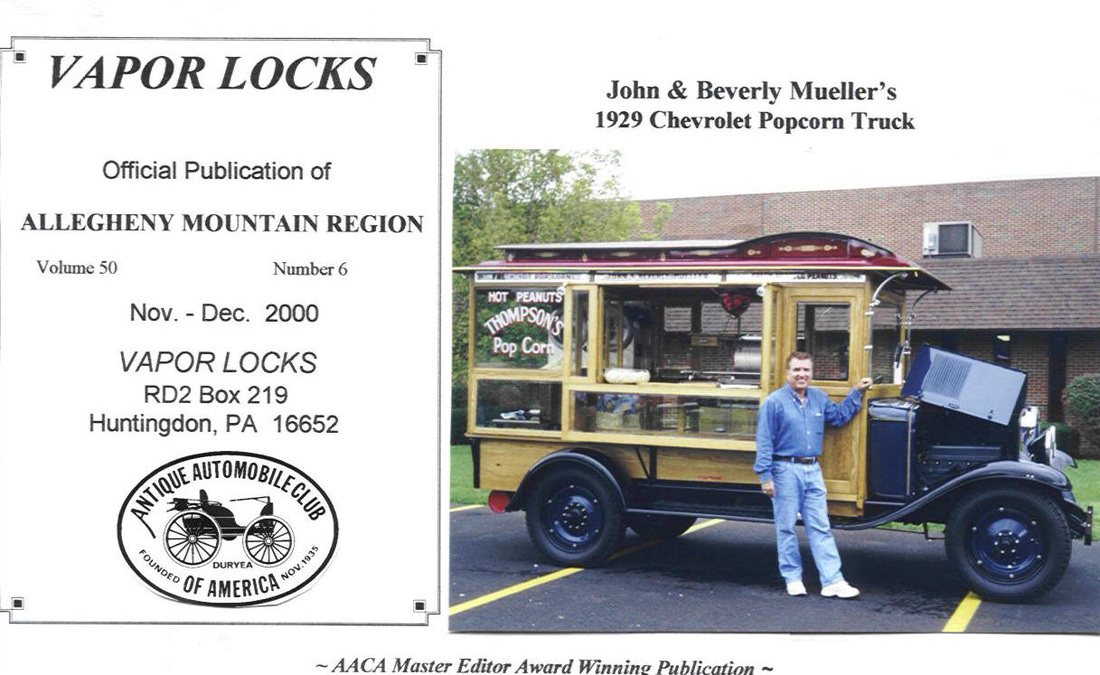

Our popcorn truck was purchased in 1929 by my wife, Beverly's, father, Jim Thompson. This was the beginning of a carnival and amusement park business that lasted for over 50 years. Click here to see a Dunbar Catalog page for the 1929 Dunbar Popcorn Model 4 Truck.

Approximately 40 of these Model 4 (truck mounted) Popcorn Wagons were produced and there are still 10 in existence. These wagons were mounted initially on Model T's with Smith Form-A-Truck conversions, on Chevrolet trucks starting in 1929, and a final wagon on a Dodge in 1949. Customers were attracted by the glass glue chipped and mirrored signs, the working 1/2 horsepower steam engine, a steam whistle, the brightly decorated coachwork, and the irresistible aroma of fresh popped popcorn and roasted peanuts.

This truck was sold at my father-in-law's estate sale in 1977. Click here for 1977 Newspaper Article about the Popcorn Wagons Sale. Beverly and I were able to buy it in 1988. We used it for a couple of years, but it was totally wore out, so we decided to do a complete frame-off restoration. We replaced only those parts that were beyond repair in order to preserve its historic value.

The restoration took eleven years and was done in my home hobby shop. I have done other frame-off restorations, but this was the most challenging as well as the most difficult. Countless hours were spent on research to find the correct parts, designs, and artwork for the popcorn wagon portion of the restoration.

First, we did the normal restoration of the Chevy body and chassis. After 60 years of use, there wasn't a piece that didn't have to be rebuilt, but this seemed easy compared to the restoration of the popcorn wagon. We started by stripping the twelve coats of varnish off the oak body, replaced the bad wood, hardware, beveled glass and chipped glass glued signs. Next, we rebuilt the white gas system, the boiler, steam engine, popcorn popper, peanut roaster, and the water reservoir. Then we did the plumbing for the steam engine, gearing, and shift levers to operate everything. One of the most time consuming components was the trolley style metal roof with its multiple levels, nine vent doors, brass rain spout, and intricate art work. Close to 500 hours were used here.

Next came the final fit and assembly and the hope of showing it at Hershey 2000. We worked really hard all summer and made it to Blend's Park for our show and were awarded first place in our class. We burned the midnight oil and made it to Hershey with one day to spare, where we were fortunate enough to receive our first Junior.

Written by John Mueller for Vapor Locks

This truck was sold at my father-in-law's estate sale in 1977. Click here for 1977 Newspaper Article about the Popcorn Wagons Sale. Beverly and I were able to buy it in 1988. We used it for a couple of years, but it was totally wore out, so we decided to do a complete frame-off restoration. We replaced only those parts that were beyond repair in order to preserve its historic value.

The restoration took eleven years and was done in my home hobby shop. I have done other frame-off restorations, but this was the most challenging as well as the most difficult. Countless hours were spent on research to find the correct parts, designs, and artwork for the popcorn wagon portion of the restoration.

First, we did the normal restoration of the Chevy body and chassis. After 60 years of use, there wasn't a piece that didn't have to be rebuilt, but this seemed easy compared to the restoration of the popcorn wagon. We started by stripping the twelve coats of varnish off the oak body, replaced the bad wood, hardware, beveled glass and chipped glass glued signs. Next, we rebuilt the white gas system, the boiler, steam engine, popcorn popper, peanut roaster, and the water reservoir. Then we did the plumbing for the steam engine, gearing, and shift levers to operate everything. One of the most time consuming components was the trolley style metal roof with its multiple levels, nine vent doors, brass rain spout, and intricate art work. Close to 500 hours were used here.

Next came the final fit and assembly and the hope of showing it at Hershey 2000. We worked really hard all summer and made it to Blend's Park for our show and were awarded first place in our class. We burned the midnight oil and made it to Hershey with one day to spare, where we were fortunate enough to receive our first Junior.

Written by John Mueller for Vapor Locks